New Material Offered - PC/ABS Blend

- May 19, 2020

- 2 min read

We have added an additional product to our lineup. We have successfully molded a polycarbonate and acrylonitrile butadiene styrene blend of plastic.

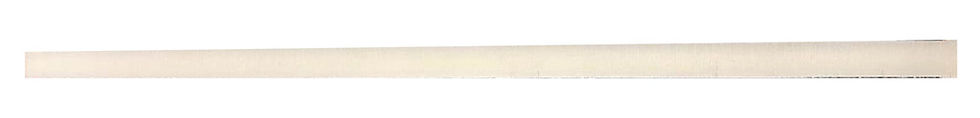

This material is ideal for automotive and electronic applications. It is heat resistant and has high impact strength. PC/ABS blend is known for being difficult to injection mold, but using our own unique proprietary color blending and molding technology, we have manufactured a high-quality rod with minimal to no internal stress. Our process includes drying the virgin material, and injection molding at a temperature and speed that is unique to our technology. The rods manufactured, as pictured below, have been quality tested to ensure that they are free of voids.

The benefit of blending polymers is an improvement in strength and impact resistance. Polycarbonate is an expensive material due to it’s chemical properties. Blending with ABS reduces cost to consumers, while providing a material that is suitable for heat resistance. We are currently making 1” x 24” rods with plans to expand sizes to additional diameters, and blocks.

Plasti-BlockTM plastic rods are suitable for producing high quality parts using techniques such as manual and CNC machining, milling, heat gun shaping, bending, etc.

As always, we are available for custom sizes and blends of materials. If you require a material that we do not have listed, please inquire using our form, or click our chat option to speak with a live employee, Monday to Friday 9-5 EST. Inquiries can also be directed to support@plastiblocks.ca.

Comments